Lean

Lean is the principle of eliminating waste and continuously improving the process.

Daily Management Systems

Daily Management System is a structured approach for an organization to ensure daily operations go according to plan.

5s

Sort, Set, Shine, Standardize, Sustain.

5s is the philosophy of keeping an organization functional with an organized and structured format which leads to a safe, low cost, and efficient work place.

Value Stream Mapping

Value Stream Mapping (VSM) is a Lean tool used to analyze and improve the flow of materials and information required to deliver a product or service to the customer. It focuses on identifying and eliminating the three types of waste — Muda (non–value-added activities), Muri (overburden), and Mura (unevenness) — to achieve a smoother, more efficient process.

By applying the five principles of Lean, VSM helps organizations:

1. Identify value from the customer’s perspective.

2. Map the value stream to visualize all value-added and non–value-added steps.

3. Understand how value flows through each stage of the process.

4. Establish a pull system that produces only what is needed, reducing waste.

5. Create standards for continuous improvement and the pursuit of perfection.

Through this process, teams gain insights into key performance measures such as cycle time, takt time, lead time, and the proportions of Value-Added (VA%), Non–Value-Added (NVA%), and Business Value-Added (BVA%) activities.

Makigami

The Makigami process is a visual method for mapping and analyzing end-to-end business processes, including information and material flow. Its purpose is to identify waste, inefficiencies, and improvement opportunities across departments. By doing so, it helps businesses streamline workflows, enhance collaboration, reduce waste, and improve overall efficiency and customer value.

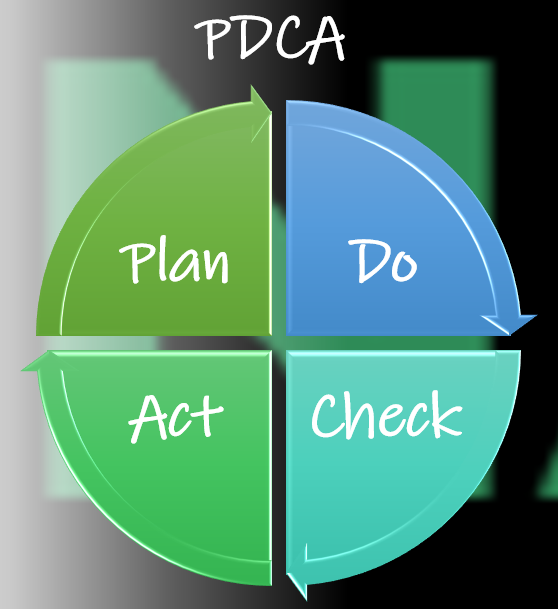

PDCA (Plan, Do, Check, Act)

PDCA cycle is a model for carrying out a change. It is commonly used for continuously improving systems, processes, and methods.

Plan - It is the most crucial step. This step recognize defining opportunities and creating a plan.

Do - This step involves stakeholders with timelines to execute the actions to achieve the plan.

Check - This step requires the stakeholders to verify the results by measuring and evaluating the results.

Act - This step requires reviewing and making a decision if the action achieved the plan.

Thus the PDCA cycle continues

Kaizen

The Kaizen process is a structured, continuous improvement method that engages teams in identifying and solving problems to enhance efficiency, quality, and performance. It begins with assembling a Kaizen team, defining the problem, and collecting data to understand the current situation. An A3 document is created to summarize findings, and the team visits the Genba (the actual workplace) to observe processes firsthand. They then identify sources of waste (Muda), unevenness (Mura), and overburden (Muri), analyze critical factors, and prioritize improvement actions. After piloting and validating improvements, the changes are implemented and provisional standards are created. The team revisits results at 30-, 60-, 90-, and 120-day intervals to confirm effectiveness and establish permanent standards, ensuring lasting improvement.