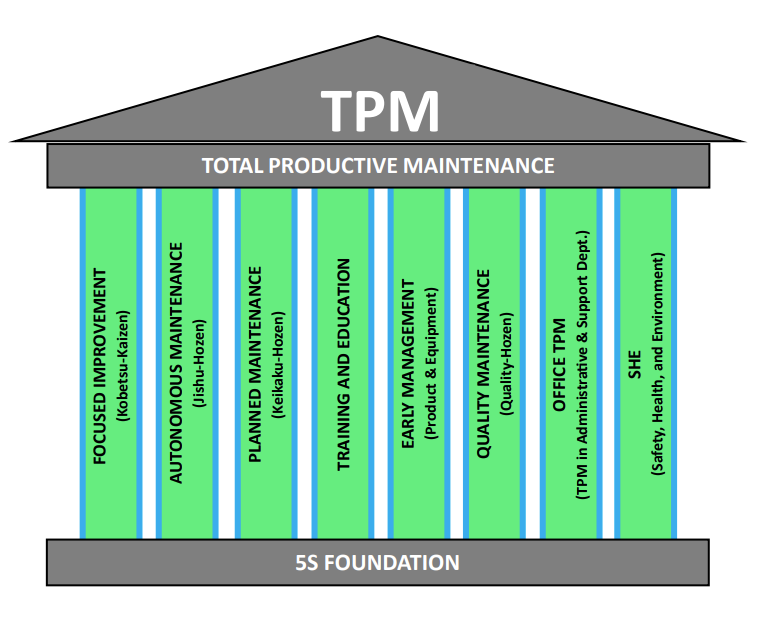

TPM (Total Productive Maintenance)

The principle of Total Productive Maintenance is total participation of all associates to build a profitable operation, practice prevention rather than cure, hands on shop floor approach, involve everyone, and treat everyone with respect.

8 Pillars of TPM

Focused Improvement (Kobetsu-Kaizen)

Focused Improvement is an essential pillar of TPM that drives the organization toward zero losses, engaged associates, and a problem-solving culture. It systematically identifies and eliminates the root causes of losses in equipment, processes, and operations through continuous improvement activities known as Kaizens.

This pillar empowers teams to analyze and reduce chronic issues using structured root cause analysis tools such as Ishikawa (Fishbone) diagrams, Five WHYs, and Failure Modes and Effects Analysis (FMEA). These methods help uncover the underlying causes of inefficiencies, defects, and breakdowns, allowing associates to develop and implement effective focused improvement ideas.

By engaging all associates in problem-solving and continuous improvement, the Focused Improvement pillar strengthens ownership, enhances productivity, and supports the TPM goal of achieving zero breakdowns, zero defects, and zero accidents.

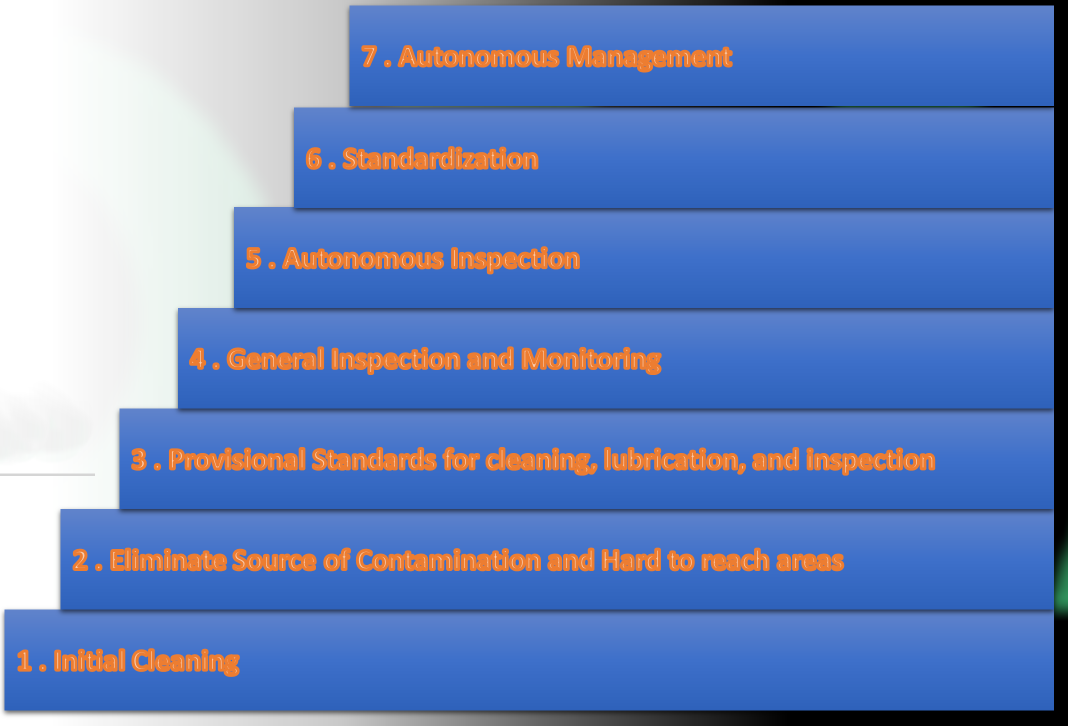

Autonomous Maintenance (Jishu-Hozen)

Autonomous Maintenance is a core TPM pillar that empowers operators to take ownership of their equipment by performing routine maintenance tasks independently. Its goal is to ensure equipment reliability, prevent deterioration, and build operator skills and accountability, ultimately contributing to zero breakdowns and a culture of engaged, proactive maintenance.

The process begins with Initial Cleaning, where operators thoroughly clean machines to expose and identify abnormalities. This leads to actions to Eliminate Sources of Contamination and Hard-to-Reach Areas, ensuring lasting cleanliness and easier maintenance access.

Operators then establish Provisional Standards for Cleaning, Lubrication, and Inspection, creating consistent routines for daily care. Through General Inspection and Monitoring, they learn to detect early signs of wear, leaks, or looseness. As skills mature, operators progress to Autonomous Inspection, performing systematic checks without direct maintenance support.

Finally, the process advances through Standardization and Autonomous Management, where operators integrate maintenance into their daily work, manage performance data, and continuously improve equipment conditions.

Together, these steps develop capable, responsible teams who sustain equipment health, extend asset life, and support the TPM vision of zero losses and continuous improvement.

Planned Maintenance (Keikaku-Hozen)

Planned Maintenance is a key pillar of TPM focused on preventing equipment failures and ensuring high reliability through systematic, data-driven maintenance practices. It aims to transition from reactive maintenance to proactive strategies, thereby reducing unplanned downtime, optimizing costs, and supporting Autonomous Maintenance activities.

The Seven Steps for Planned Maintenance (Keikaku-Hozen) provide a structured roadmap for achieving these goals:

- Learn and Understand Equipment Failures: Analyze historical data to identify common failure modes and patterns.

- Implement Root Cause Analysis: Use analytical tools to determine and eliminate the underlying causes of equipment failures.

- Correct Weaknesses of the Equipment: Improve equipment design or conditions to enhance reliability and maintainability.

- Educate Operators and Develop Standards for Inspections: Train operators in General Inspections and create clear, standardized maintenance procedures.

- Establish Periodic Maintenance (Time-Based Maintenance, TBM): Schedule maintenance tasks at fixed intervals to prevent deterioration.

- Implement Predictive Maintenance Systems (Condition-Based Maintenance, CBM): Introduce diagnostic technology to monitor performance and predict failures using trends and reliability data such as alpha and beta values.

- Optimize the Planned Maintenance System: Continuously refine maintenance frequency, methods, and standards to maximize effectiveness.

Planned Maintenance also integrates and manages the Types of Maintenance, including: Periodic Maintenance (Time-Based Maintenance, TBM) — Performed at regular, set intervals. Predictive Maintenance (Condition-Based Maintenance, CBM) — Based on actual equipment condition and performance data. Breakdown Maintenance — Performed after equipment failure to restore function. Corrective Maintenance — Involves improving or redesigning equipment to prevent recurrence of failures.

By implementing these practices, Planned Maintenance minimizes unplanned downtime, extends equipment life, and ensures that maintenance is predictable, efficient, and aligned with production goals — forming a strong foundation for achieving zero failures and continuous improvement.

Training and Education

The Training and Education pillar focuses on developing the skills and knowledge of all associates to effectively perform their job functions and sustain continuous improvement. It involves creating a skill matrix to identify development needs, establishing a training timeline to guide learning, enhancing essential training documents for clarity and consistency, and setting a schedule to audit skills and ensure retention. The ultimate goal is to build a skilled, confident, and self-reliant workforce that drives TPM excellence and supports a culture of zero losses and continuous improvement.

Early Management (Product and Equipment)

The Early Management pillar is an essential component of TPM that engages operators and maintenance teams early in the design and development stages of new equipment and processes. Its purpose is to capture early learnings, improve design reliability, and ensure smooth start-up of capital investments. Key activities include establishing a CQV (Commissioning, Qualification, and Verification) document to validate equipment performance, learning the OEM’s equipment Cpk value (quality index) to assess design capability, and conducting both Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) to confirm operational readiness. The pillar also focuses on equipment performance verification through measures such as Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and Availability. By integrating these practices, Early Management ensures that new assets achieve stable operation quickly, with higher reliability, maintainability, and quality from day one.

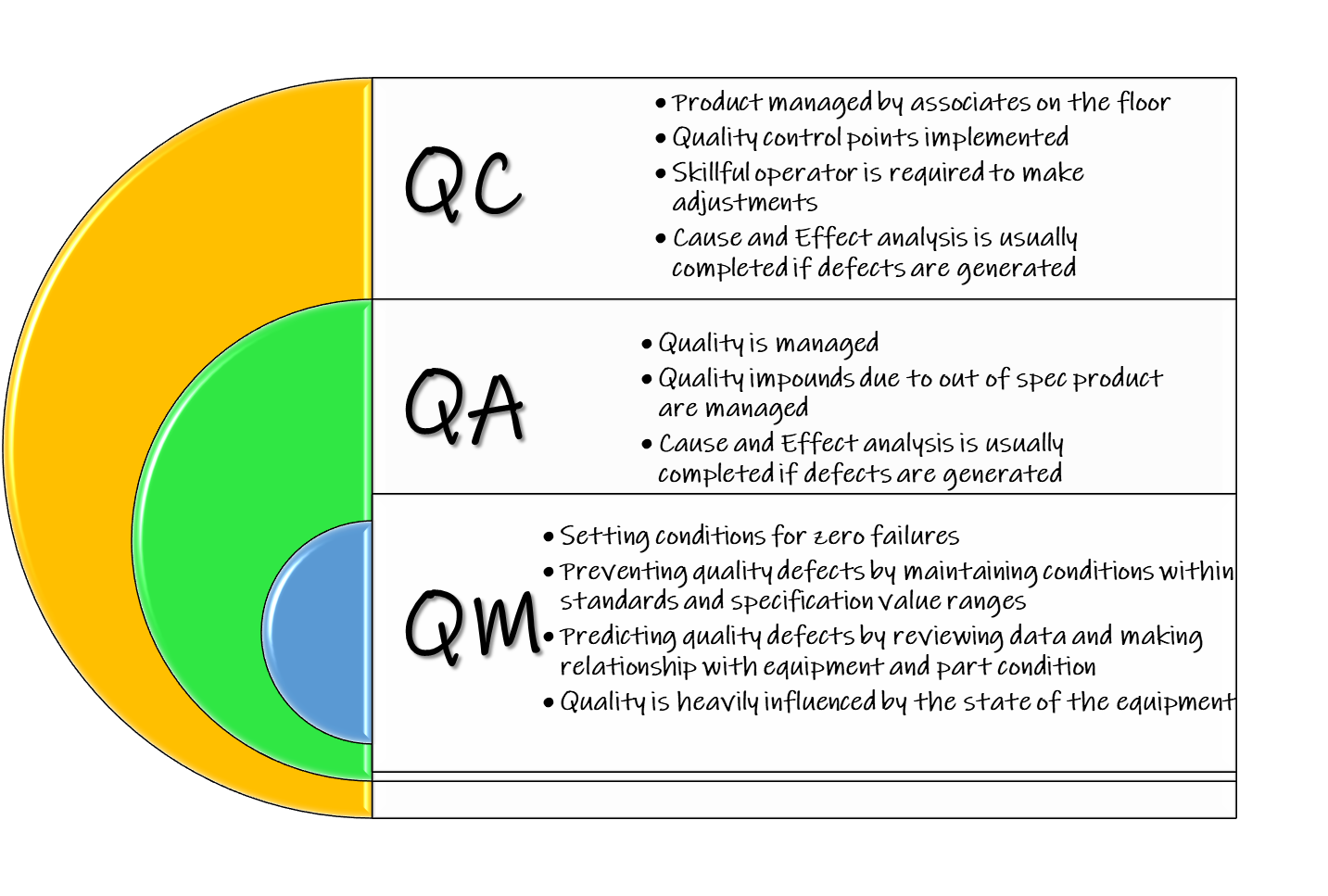

Quality Maintenance (Quality-Hozen)

The Quality Maintenance pillar is an essential component of TPM focused on achieving zero quality defects by ensuring every process and piece of equipment consistently produces products that meet specifications. It aims to eliminate stops between each equipment, ensuring smooth, defect-free flow throughout production. This pillar emphasizes implementing effective controls to eliminate quality defects, creating a compliant and reliable process that prevents errors rather than detecting them. Through the strong application of Six Sigma tools and the development of a Quality Maintenance (QM) Matrix, teams identify potential sources of variation and implement measures to maintain product integrity. Ultimately, Quality Maintenance strengthens process capability, enhances customer satisfaction, and supports the TPM goal of delivering products right the first time, every time.

Office TPM (TPM in administrative and support departments)

The Office TPM pillar is an essential component of TPM focused on administrative and office processes that support overall organizational efficiency. It helps optimize supplier and warehouse management and ensures effective total management of the supply chain. Key practices include Value Stream Mapping to improve supply chain flow, Mass Balancing to track materials accurately, and monitoring Takt Time, Cycle Time, and Lead Time to enhance process efficiency. Additionally, the pillar emphasizes Inventory Control to reduce waste and ensure timely availability of materials. By applying TPM principles in the office environment, organizations can streamline administrative operations, support production reliability, and maintain a seamless, efficient supply chain.

SHE (Safety, Health, and Environment)

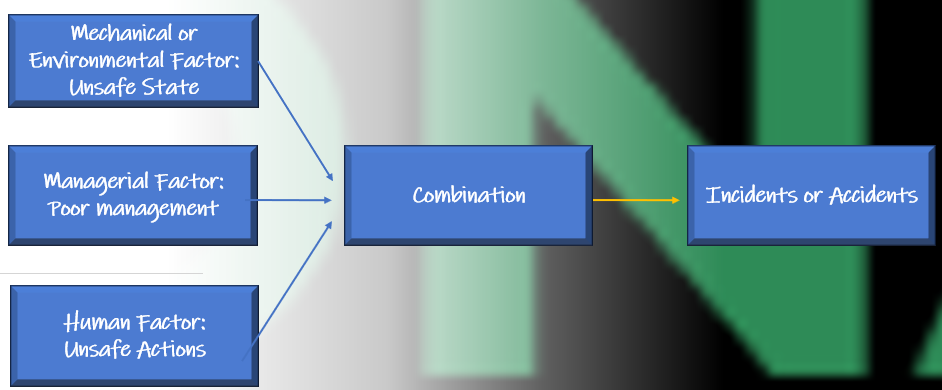

The Safety, Health, and Environment (SHE) pillar is an essential component of TPM focused on achieving zero accidents and creating a safe, healthy, and sustainable workplace. It ensures that all operations are free from hazards and safety risks, while also promoting zero pollution through responsible environmental practices. By integrating safety and environmental considerations into every aspect of work, this pillar protects associates, enhances operational reliability, and supports a culture of continuous improvement.