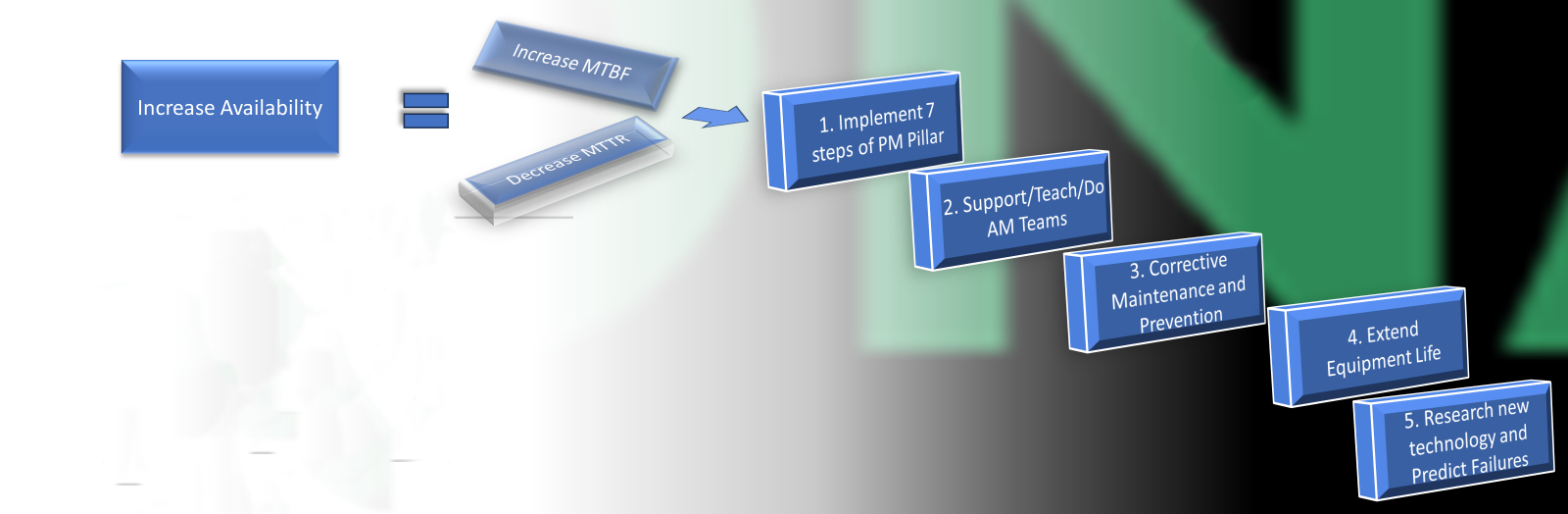

Seven steps for Planned Maintenance (Keikaku-Hozen)

- Support Autonomous maintenance

-

Learn and understand the equipment failures

- Implement root cause analysis

- Correct weaknesses of the equipment

- Educate Operators in general inspections and develop standards for inspections

-

Establish Periodic Maintenance

- Implement frequency of maintenance inspections

- Time Based Maintenance (TBM)

-

Implement Predictive Maintenance System

- Introduce diagnostic technology and learn failure behavior based on alpha and beta values

- Condition Based Maintenance (CBM)

-

Optimize Planned Maintenance system

- Establish Corrective Maintenance

Types of maintenance

- Periodic Maintenance (Time based maintenance)

- Predictive Maintenance (Condition based maintenance)

- Breakdown Maintenance

- Corrective Maintenance